How to manufacture metal injection mold?

Metal injection mold manufacturing involves several stages. Generally, the following steps are followed:

Design: The design of the injection mold is done based on the shape, size, and features of the part. The design is created using 3D CAD software.

Mold block manufacturing: The mold blocks are manufactured using materials such as steel, aluminum, or stainless steel.

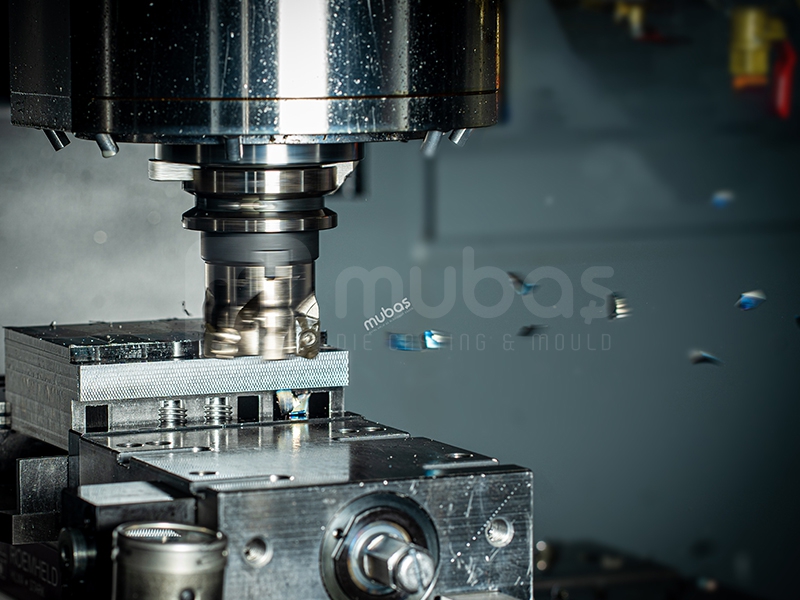

Mold machining: The mold blocks are machined to shape them to the desired form and dimensions of the part.

Mold cutting: The required holes in the mold are cut using tools such as milling machines or electric saws.

Mold finishing: The mold is finished by applying various treatments such as polishing, hardening, or electroplating.

Mold testing: The mold is tested to ensure that the parts are cast correctly and with precision.

Mold preparation for use: The mold is assembled and checked for use in the casting machine.

Production: The mold is used for mass production using injection molding process.

It is important to note that the process of manufacturing an injection mold is complex and requires a good understanding of the design, materials and machining techniques. A well-designed and manufactured mold will ensure accurate and consistent casting of parts.